Stainless Sanitary,Food Tubes

Application: Dairy & Food Industry. Heavily cold worked welded stainless steel sanitary tubing with special surface finishes. Pharmaceutical quality - Supplementary requirement i.e Inside Polishing can be requested. Seamless tubes (if required) for sanitary applications can be supplied on request. Dairy/Food Tubes & Fittings are Supplied in following grades:

■ Austenitic Grade 304, 304L, 316, 316-L.

■ Duplex (Ferritic/Austenitic) - Specific Jobs/Project - Discuss with sales office.

Australian Standard - AS-1528.1 - Improved from ASTM A270 Specifications covers both Tube/Fittings. It is a requirement for application in the Australian Food/Dairy Industy supplied from mills capable of producing quality product competitively priced.

Delivery Lead Times - Production 2 Weeks to 8 weeks + Shipping - Refer sales office for firm commitments.

Ex Stocks - Delivery 2 - 5 Days from order - Contact our sales office. Min Qty Applies.

(Tubes & Fittings to suit)

| Stainless Steel Sanitary Tubes (Dairy/Food Industry). | ||||||||||

| Specifications: ■ AS1528.1 (Aust Std) ■ ASTM A270 ■ EN 10217/7■ DIN11850 ■ CNS 6668 G3131. | ||||||||||

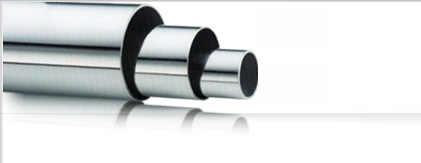

| ROUND TUBES. | Surface Finish-(OD): MF, 2-B, Pol 180 Grit, 320#, 400#, 600# | |||||||||

| Inside Diameter - Bead Removed/Rolled. Polished 400" on Request. | ||||||||||

| AS-1528.1 - Spec Strictly applicable for Food & Dairy Industry in Australia. | ||||||||||

| TH | Thickness/厚度/Tebal | |||||||||

| OD | in | 0.0475 | 0.0490 | 0.0590 | 0.0650 | 0.0787 | 0.0830 | 0.1180 | 0.1200 | |

| in | mm | mm | 1.2 | 1.25 | 1.5 | 1.65 | 2.0 | 2.11 | 3.0 | 3.05 |

| 1" | 25.4 | |||||||||

| 1 1/4" | 31.8 | |||||||||

| 1 1/2" | 38.1 | |||||||||

| 2" | 50.8 | |||||||||

| 2 1/2" | 63.5 | |||||||||

| 3" | 76.2 | |||||||||

| 3 1/2" | 89.1 | |||||||||

| 4" | 101.6 | |||||||||

| 5" | 127 | |||||||||

| 6" | 152.4 | |||||||||

| 8" | 204 | |||||||||

| Note: (Refer to European Spec Large Diameter Thin Wall Tubing) Link>>> | ||||||||||

| *Diamentional Tol: Refer Specifications Link>>> | ||||||||||

| AS-1528.1 - Specification Details - Refer Under "Tab" Specifications. | ||||||||||

| *For Specific Project/Fabrication Requirement, Reliable Delivery Lead Timings | ||||||||||

| - Approx 2-3 Weeks Ex Mill + Shipping, Contact Sales Office to Discuss. | ||||||||||

| * Tube BW Fittings, Flanges & Valves - Refer Link>> | ||||||||||

1. Excellent Consistent Quality of Product.

2. Custom Size cut Lengths - Save on Offcuts.

3. Short Delivery Lead Time - If Necessary.

Ex Stocks Available - Contact sales office for Quantities/Availabilities.

4. Custom Line Markings on Tube.

5. Choice of Packaging.

6. Good Documentation.

7. Competitive Price.

STANDARDS

1. AS 1528 - Australian Standard Tubes (stainless steel) and tube fittings for

the food industry. - Brief details of this spec listed below.

2. ASTM A270 - American Standards of Testing Material. Standard Specificaion

for Seamless and Welded Austenitic and Feritic/Austenitic Stainless Steel Sanitary Tubing.

3. EN 10217/7 - European Standards. Welded Steel Tubes for Pressure Purposes. Technical Delivery Conditions Part - 7: Stainless Steel Tubing.

4. DIN 11850 -(Deutsches Institut für Normung), meaning "German institute for standardisation" Stainless Tubing - Metric Sizes.

5. CNS 6668 G3131 - China National Standards.

| SPECIFICATIONS. AUSTRALIAN STANDARDS 1528.1 (AS 1528) TUBE & FITTINGS FOR THE FOOD/DAIRY INDUSTRY. (Seamless or Welded). | |||||

| ■ MATERIAL - Tubes shall be manufactured from Austenitic or Duplex Stainless in compliance with requirements specified for the relevant grades in ASTM A240M. | |||||

| ■ WELDED TUBES - Process of Manufacture: Welded by an inert gas protected fusion process without the use of filler rod. All welds shall have 100 % weld penetration, Weld Bead shall be internally cold worked. The weld profile shall be continuous and merge into the inner surface profile of the tube. | |||||

| ■ CONDITIONS OF SUPPLY - Tubes shall be supplied in either cold worked or in the cold worked solution annealed condition as specified by the purchaser. Cold worked on the weld only is acceptable. | |||||

| ■ NOTE: Tubes sizes 12.7mm OD - 25.4 mm OD are not cold worked. For any critical applications, Seamless or Hammer swaged tubes may be considered. | |||||

| ■ Straightness Tolerance: Within 1 mm in 500 mm Long. | |||||

| ■ Ovality Tolerance: Maximum & minimum of any cross-section shall deviate from the nominal diameter by no more than twice the permissible variation in outside diameter. The mean diameter at the cross-section shall be within the given permissible variation. | |||||

| PHYSICAL DIMENSIONS AND TEST PRESSURE | |||||

| Outside diameter nominal mm | Outside diameter tolerance mm | Wall thickness nominal mm | Wall thickness tolerance mm | Cut Length tolerance mm | Test Pressure Mpa |

| 12.7 | ± 0.13 | 1.60 | + nill. - 0.10 | - 0, + 3 | 26.9 |

| 19.34 | ± 0.13 | 1.60 | + nill. - 0.10 | - 0, + 3 | 18.00 |

| 25.4 | ± 0.13 | 1.60 | + nill. - 0.10 | - 0, + 3 | 13.5 |

| 31.8 | ± 0.13 | 1.60 | + nill. - 0.10 | - 0, + 3 | 10.8 |

| 38.1 | ± 0.25 | 1.60 | + nill. - 0.10 | - 0, + 3 | 9.0 |

| 50.8 | ± 0.25 | 1.60 | + nill. - 0.10 | - 0, + 3 | 6.7 |

| 63.5 | ± 0.25 | 1.60 | + nill. - 0.10 | - 0, + 3 | 5.4 |

| 76.2 | ± 0.25 | 1.60 | + nill. - 0.10 | - 0, + 3 | 4.5 |

| 101.6 | ± 0.38 | 1.60 | + nill. - 0.10 | - 0, + 3 | 3.4 |

| 127.0 | ± 0.38 | 1.60 | + nill. - 0.10 | - 0, + 3 | 2.7 |

| 152.4 | ± 0.76 | 1.60 | + nill. - 0.10 | - 0, + 3 | 2.2 |

| 203.2 | ± 0.76 | 1.60 | + nill. - 0.10 | - 0, + 3 | 2.2 |

| Notes: | |||||

| ● Tolerance on Cut Lengths: Up to & including 7.3 M. For Lengths over 7.3 M - Additional Length tolerance of 3 mm will apply for Ea 3 M or fraction up to a maximum of 13 mm. | |||||

| ● Tolerance on Standard Mill Lengths: - 0, + 35 mm. | |||||

| ● Wall thickness may be varied by negotiation with supplier. | |||||

| ● Internal Surface: Tubes shall be manufactured from Cold Rolled 2-B Finish strip ( equavalent to 0.3 µm Ra. Profile of the weld bead shall be continuous with the internal surface of the tube without any evidence of undercut, scoring or noticeable roll marks. | |||||

| ● Contaminants: Tubing shall be manufactured & handled in a manner that will avoid ferrous & other contaminants. | |||||

| ● Defects: Tubes shall be clean & smooth. Shall be free from harmful surface defects, inclusions & longitudinal grooving. | |||||

| ● Heat Treatment: IF called for by purchaser/buyer the tubes shall be annealed. The annealing treatment for the austenitic stainless shall be heating of tubes to 1040 ͦ minimum followed by rapid cooling. Annealing of Duplex stainless may be specified by agreement. | |||||

| ● Testing: Welded Tubes:- Non Destructive Testing - Unless specified by the purchaser/buyer of the type of test to be conducted, The manufacturer at his or her option can carry out either Eddy Current Test or Hydrostatic Test in Accordance with ASTM A-269. Tubes shall be capable of withstanding an internal pressure without leaking to the equation : | |||||

| P = 220.6t/D where: | |||||

| P = pressure. In megapascals. | |||||

| t = wall thickness. | |||||

| D = diameter (see Table above) | |||||

| SSM will not be held responsible for any variation or changes on the figures/details listed above. Please refer to AS 1528.spec which can be secured from ASSDA. | |||||

Sanitary Tubing & Fittings are supplied in the following grades:

■ Austenitic: 304, 304-L, 316, 316-L

■ Duplex (Ferritic/Austenitic): 2304, S32304,W-Nr1.4362, 2205, S31803/S32205, W-Nr 1.4462

Refer sales office for any special requirments.

Please contact sales office if reference required.